PEC – Engineering

1. BVH Wieser

The company Wieser in Scheffau am Tennengebirge, Salzburg, had to expand its existing warehouse in 2021-22 to accommodate an order that required the assembly and testing of a production line over 100 meters long.

The adjacent company premises were classified as a “Red Zone” and needed to undergo special foundation work to protect against flooding in order to obtain a change of land use. Simultaneously, an underground garage was constructed and had to be secured against buoyancy.

The new production hall connects to the existing warehouse. In the process, a column was removed and integrated into the new hall through underpinning. The project implementation was characterized by a very limited construction site, tight time constraints, and a well-coordinated project team, notably Mr. Breitegger and Mr. Jörl.

2. SA2

Object SA2 is a viaduct located on the LB 80 at railway kilometer 82.212 of the Koralmbahn railway, in the section between St. Paul and Aich. The bridge is a prestressed two-span bridge with a squat hollow box cross-section and a total span length of L = 46.34 + 45.76 = 92.10 meters. One of the spans aligns with the curve of the LB 80, while the other is in the transition area to a counter-curve. The hollow box has a height of H = 2.0 meters and changes to H = 3.0 meters at the central abutment. The central support is rotated by a = 45° with respect to the bridge axis and is parallel to the track axes passing underneath.

Under each span, a track runs with a lateral clear distance of e = 7.0 meters to the pier. The bridge is B = 11.5 meters wide and features a walkable edge beam on both sides with a width of B_RB = 1.50 meters.

Building inspections

We have extensive experience in structural inspections, having carried out assignments across Austria. As a result, we are very familiar with the road network and have already documented many structural defects. All inspection results are recorded in a structural database, making it a valuable source of knowledge. We can provide expertise in the maintenance management of this kind of infrastructure.

Structural inspections involve both fieldwork and reporting. The added value lies in transferring the data into a statistical model. This allows us to determine lifetime distributions, assess entire networks in terms of their aging behavior, and calculate the medium-term cost requirements.

PSP – Measurement technology

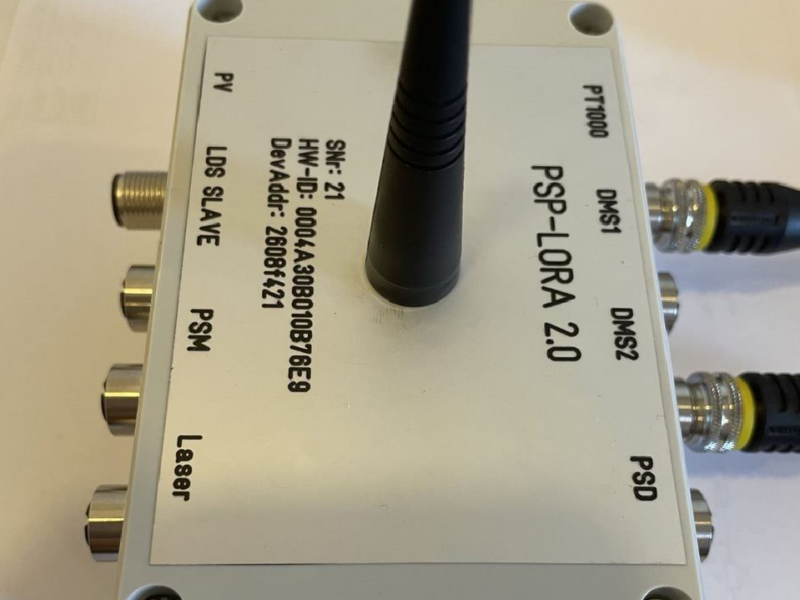

LoRA

Structural Health Monitoring (SHM) involves implementing IoT for structures. Bridges are equipped with LoRaWAN nodes for this purpose. These nodes do not require wiring and are battery-powered. They are distributed across the bridge and capture parameters such as inclinations, strains, displacements, curvature of the superstructure, or dynamic characteristics.

The sensor data is transmitted as data packets at a specific radio frequency to a gateway, either statically at regular intervals or dynamically. The gateway forwards the data to a network server. After further processing and storage in a database, the information is made available. Statistical analyses are then conducted based on this data.

In essence, SHM utilizes IoT technology to monitor and assess the health and structural integrity of infrastructure like bridges, making it a valuable tool for maintenance and safety assurance.

BASt

In 2022-2023, twenty BWIM (Bridge Weigh-in-Motion) measurements were conducted on the German highway network for BASt (Bundesanstalt für Straßenwesen). These measurements involved collecting truck weight data over a period of two weeks. The collected data was transmitted in a specialized binary format for further statistical analysis.

Each measurement covered two lanes in both directions on the A2, A4, and A9 highways. They were positioned in different sections and each had two active measurement cross-sections. Data collection was carried out using four iBWIM Spider 5.0 systems, each equipped with a laser for axle recognition and eight measuring sensors. Power was supplied via Off-Grid methanol cells. The project was conducted in cooperation with iSEATec in a joint venture.

PSP – Software

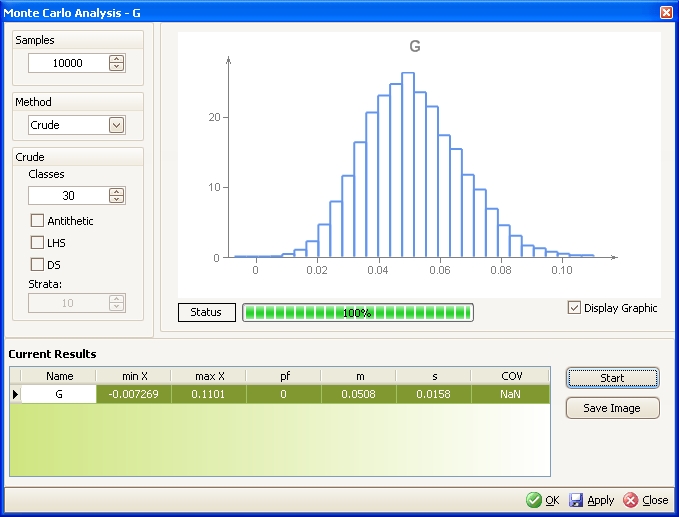

VaP – Variables Processor

The program VaP (Variable Processor) deals with the numerical process of variable Xi in algebraic defined functions G(Xi). VaP 3.0 calculates the expected value, the standard deviation and where applicable higher moments of G. It shows the form of the distribution density G and calculates the probability pf that G gets less than zero. Correlations between variables are entered. The definition of several methods during the runtime is possible. These functions lead to logical systems Sys{Gk}, which can be provided with update instructions, Gup{G|E}. The conception of VaP led to a new solution and resulted in the development of interactive software. The interface to the computer is limited to a minimum of functions and dialogues.

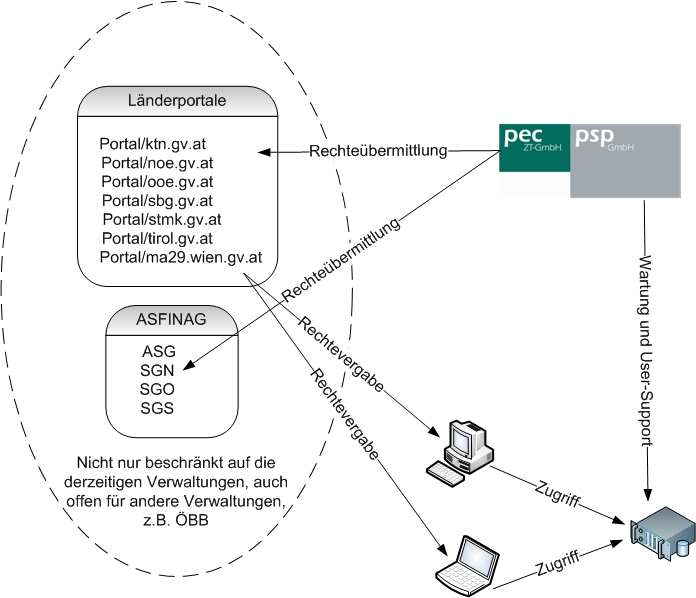

BAUTonline

BAUT online is a central, RVS conformal database WEB solution, which enables a rapid, modern and straightforward data access. BAUT online runs via a portal network.

PSP – Research & Development

SAW Sensor

A special class of MEMS sensors are Surface Acoustic Wave (SAW) sensors, which utilize the modulation of acoustic waves to measure physical characteristics. Their advantages include robustness and the absence of any electronic components, making them suitable for use in harsh environments. The current research project aims to develop such a sensor for measuring in-situ stresses in concrete structures. The sensor will provide information about RFID, temperature, and in-situ stress of the concrete. An example application is a road bridge with a concrete overlay for load-bearing capacity enhancement. The sensor is embedded in the concrete and fulfills an important role right from the start. Continuous measurements monitor the temperature during the concrete curing process and can be used for assessing the concrete’s strength development (maturity). Subsequently, the automatically collected stress and temperature data are used for Structural Health Monitoring or can be retrieved on-site as needed.

Wireless Sensors

If Structural Health Monitoring is to be carried out for road and railway bridges, it means that sensors must be distributed over a large length without the need for wiring. Instead, self-powered sensor nodes are mounted on the structure. The PSP-IOT node has been specifically designed for such challenges. Optional sensors for strain, 3D accelerations, 3D inclinations, displacement, and curvature can be activated. The data is transmitted in the MQTT protocol via LTE-M after its acquisition.

With a node, static or dynamic measurements can be performed over an extended period. The static operating mode involves regular polling of the sensors activated on the node, providing quasi-static values. In the dynamic mode, a short-time history of strains, inclinations, or accelerations is recorded, triggered by a threshold crossing.

The nodes are time-synchronized and operate autonomously. All electronic components are of the highest quality, and the sensors provide measurements of high accuracy and stability.